Retrofit Legacy RTUs Without Lifting a Wire

PUBLISHED ON Sep 03, 2020

Latest advancements in RTU design enables simplified retrofit of legacy D20, ACS, Systems Northwest, Telvent and other RTU brands without replacing existing wiring

For decades, Remote Terminal Units (RTUs) have been utilized in substations to monitor circuit breaker positions, alarms, voltages/currents, temperature and other data from a variety of wired sensors, or to control breakers, tap changers, and capacitor banks. These remote, real-time data enabled operators to perform supervisory control and data acquisition functions remotely.

However, with the earliest RTU implementations dating back to the late 1970’s, many legacy systems are no longer supported by the original manufacturers and spare parts can be difficult to acquire. In addition, continued advancements in the processing power and control capabilities of modern RTUs mean these units can often eliminate additional boxes, such as HMIs, Alarm Annunciators, Security Gateways, Logic Controllers and Communications Processors.

As a result, transmission and distribution substations that rely heavily on legacy RTUs are ripe for upgrade. Unfortunately, the task traditionally meant not only replacing the RTUs, but also disconnecting and reconnecting hundreds of wires to monitored and controlled devices.

“Even medium-sized distribution substations can have 200-300 I/O points that need to be monitored by RTUs,” according to Ray Wright, VP of Product Management at NovaTech, a leading provider of substation automation solutions. “The larger transmission substations can have well over 1000, so the magnitude of an RTU retrofit can be significant. In addition to the efforts to re-wire, there’s also the need in transmission to check out each re-wired circuit using skilled personnel in a costly and time-consuming commissioning process, and possibly applying for an outage. As a result of these high costs, utilities have stretched the service life of legacy RTUs to the breaking point, increasing the chances of disruptive failure and loss of real-time substation visibility.”

In response, leading substation automation manufacturers have developed retrofit solutions that allow the replacement of legacy RTUs with modern alternatives without the need for re-wiring.

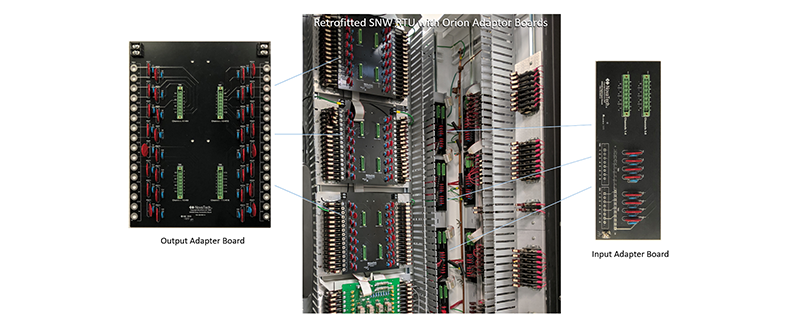

One innovative solution from NovaTech allows for the replacement of legacy RTUs – including D20, Telegy, ACS, Systems Northwest and Telvent – with adaptor boards in the place of the legacy I/O. These adapter boards are connected to the company’s Orion I/O unit through pre-designed wire harnesses. The adaptor boards are designed so the pre-existing wire connectors from the legacy system can be removed and installed while keeping all the wiring intact.

“In most cases, the field wiring is not hardwired to the legacy I/O board,” explains Wright. “Instead, it is wired through a removable connector, which can be lifted and reconnected to the adapter board. The adaptor boards are typically designed to accommodate all of the connectors for the legacy discrete input, discrete output, analog input, and combination cards. “

In situations where field wiring cannot be removed, a “top hat” approach can be used. The top hat is a NovaTech board that is placed on top of the legacy I/O card, connecting to the I/O signal pins. These pins would normally be connected to the legacy RTU, but in retrofits is connected to the Orion RTU.

A slight modification of the above approaches is used for D20 retrofits. The D20 I/O uses four connector styles, two of which – the Phoenix-style terminal and the DB25-style – can be removed from the legacy I/O modules. In these retrofits, a 1 RU (rack unit) wide adapter plates is attached to the Orion I/O module (which is 2 RU), creating an assembly than can be retrofitted into the same panel space as the 3 RU D20 I/O. By using the same panel space, retrofits are simplified.

In some cases, minor customization and re-wiring may be required, says Wright. Given the wide range of legacy RTUs in use, new adaptor boards and wire harnesses can be required and NovaTech has the design and manufacturing capabilities to produce new boards quickly, when needed.

Tapping into advanced RTU functionality

With a modern RTU like the Orion I/O, one of the primary benefits of an upgrade is significantly enhanced automation and visualization functionality. Math and Logic can now be executed on the RTU to add needed local real-time control in the substation, including controlling tie breakers, minimizing circulating VARs, forcing settings group changes, adding complex interlocking to reclosing schemes and executing “Distribution Automation” schemes.

All this can be put into the “Smart RTU” without adding logic to protective relays or adding a separate controller. In addition, pre-configured math and logic for alarm grouping, filtering and intelligent blocking can make reported alarms more meaningful, so that they are reported only when pertinent. The math and logic style can be tailored to the application; e.g. “ladder logic” for technicians to troubleshoot interlocking, higher-level text-based math and logic for engineers to create embedded routines and “canned” routines for commonly-used functions.

Utilities can also configure the modern RTU as a “Tile Alarm Annunciator without adding yet another box. A monitor can be attached to the RTU (no PC required), and a webpage served out showing a screen of colored tiles visually displaying alarm status. Custom pages can be added to further expand local annunciation including one-line diagrams and animated IED faceplates.

Security is significantly enhanced with today’s modern RTUs as well.

“Legacy RTUs only support elementary passwords, include no security event logging, and can’t tell you when someone is logged in,” said Wright. “All that is standard fare in modern RTUs, along with secure protocols based upon public key infrastructure”.

With age diminishing the effectiveness of legacy RTUs and the opportunity for more complete remote control and monitoring with newer units, substation operators are challenged to find retrofit solutions that reduce costs and simplify the process.

Eliminating rewiring from the scope of a retrofit can save significant time and cost for the utility thereby ensuring that their RTUs will continue to provide critical remote control and management functions.